- Home

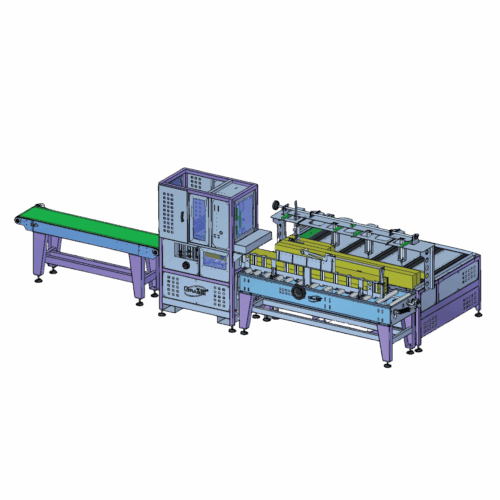

- Gluing machines

- TILTING TABLE

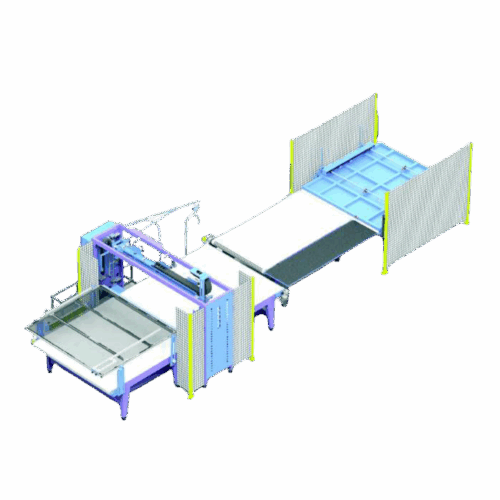

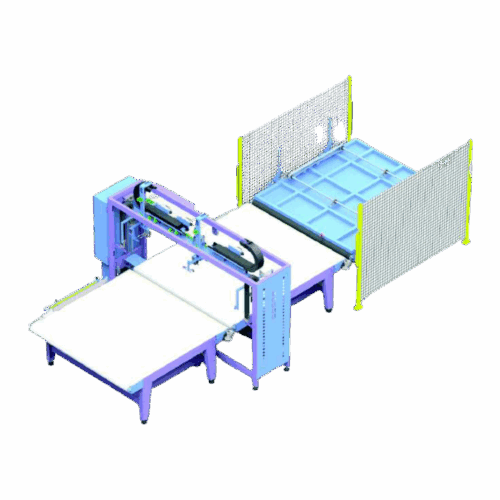

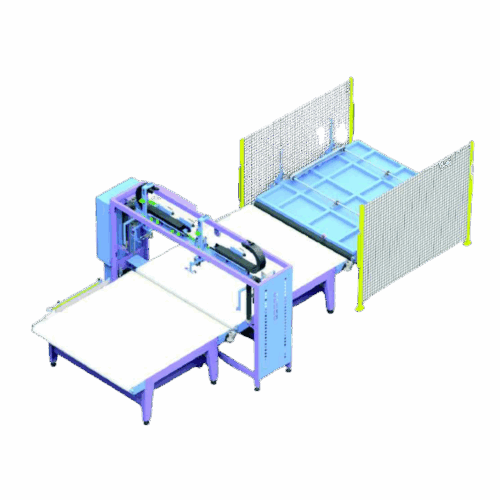

TILTING TABLE

Automatic Foam assembling machine

The TILTING TABLE is designed for the “self-assembly” of foam layers after lamination and before pressing.

It consists of three main units: an entry conveyor belt, assembling section, control panel and exit conveyor belt.

The system can work standalone, in existing gluing lines, integrated into G line series like G 7000, line G 7000 PRO or line G 6000.

It includes a control box and software for functionality management.

The operator loads the foam layers, adjusts parameters via the touch screen and oversees the assembly process.

- DIMENSIONS: 3,70×7,20xH2,40mt

- INSTALLED POWER: 5 Kw

- WEIGHT: 2300 kg

- ELECTRICAL SUPPLY: 400V + N + T – 50 / 60Hz

- AIR SUPPLY 6/8 Bar

- PRODUCTIVITY: 50mt/min