Description

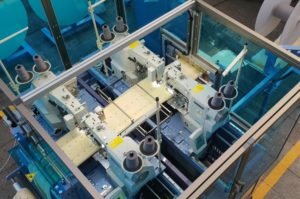

Automatic line for hot-melt glueing.

Perimeter and central.

Innovation, research and development applied to Hot-Melt create a versatile and easy to use impressive line consisting of multiple workstations to make production lean and flexible for every requirement.

With LINE G 6000 you can realize box mattresses and join sheets for mattresses of various types, latex, polyurethane, viscous, bonnel and poket springs, coconut etc. The machine independently works shaped plates from 01 to 40 cm. with automatic control of height, length and width of the incoming sheet through optical sensors.

The machine LINE G 6000 consists of:

- 2 feeding belts with 5 plies in non-stick silicone

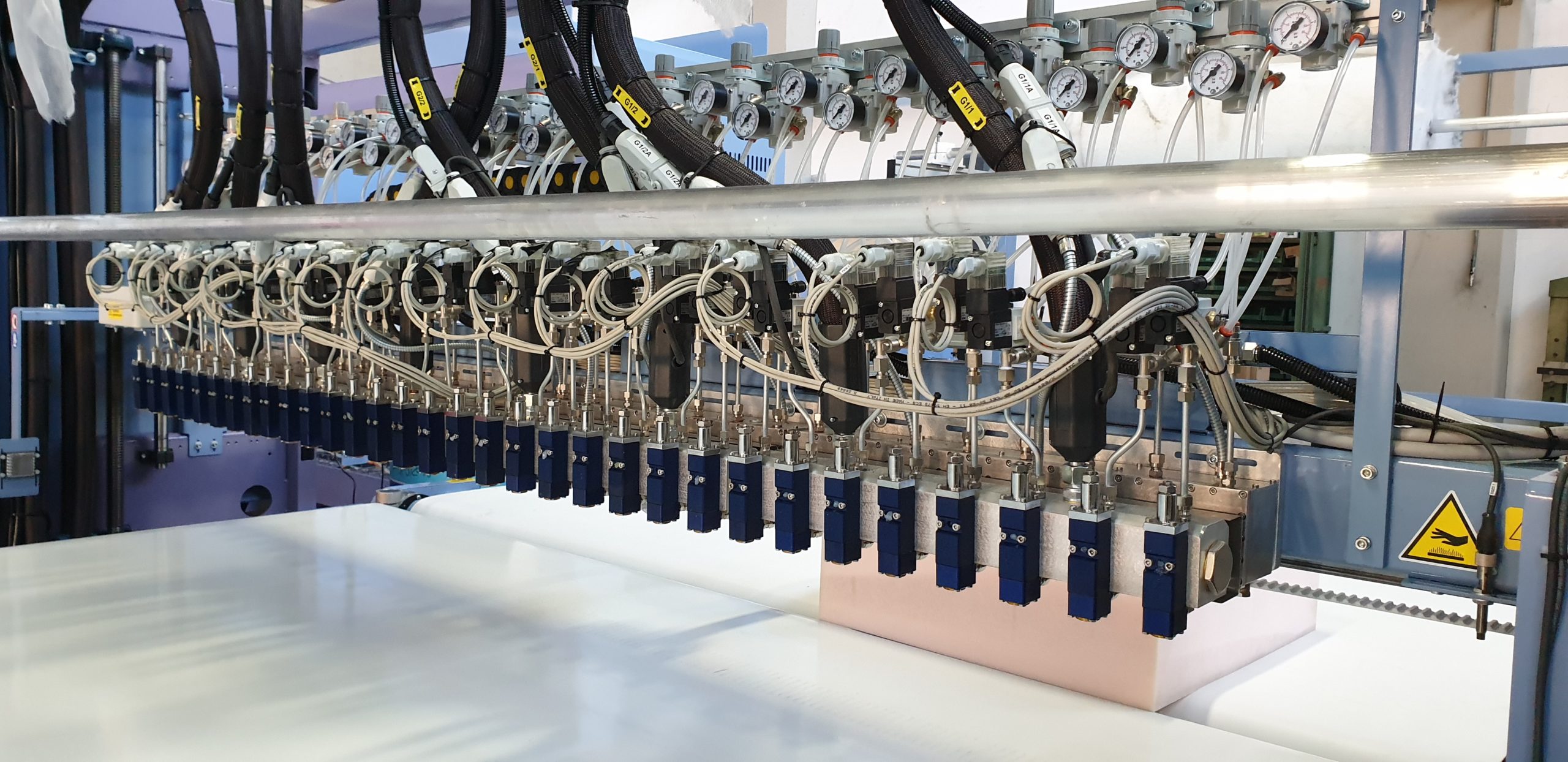

- 1 Automatic programmable glueing module complete with:

- 2 perimeter heads with 4 nozzles

- 3 central translating heads, each with 4 independent nozzles

- 1 assembly bench with 5-ply belt in non-stick silicone complete with openable side

- 1 pneumatic press to lock glued materials with programmable control of pressure and 5-ply belt in non-stick silicone

- 1 Automatic programmable glue melter, independent heating for bath, hoses and spray guns, ceramics gear pumps controlled by a microprocessor.

AVAILABLE VERSIONS:

LINE G 6000: Standard automatic line for hot-melt glueing

LINE G 6000 S: Simplified line for hot-melt glueing