Description

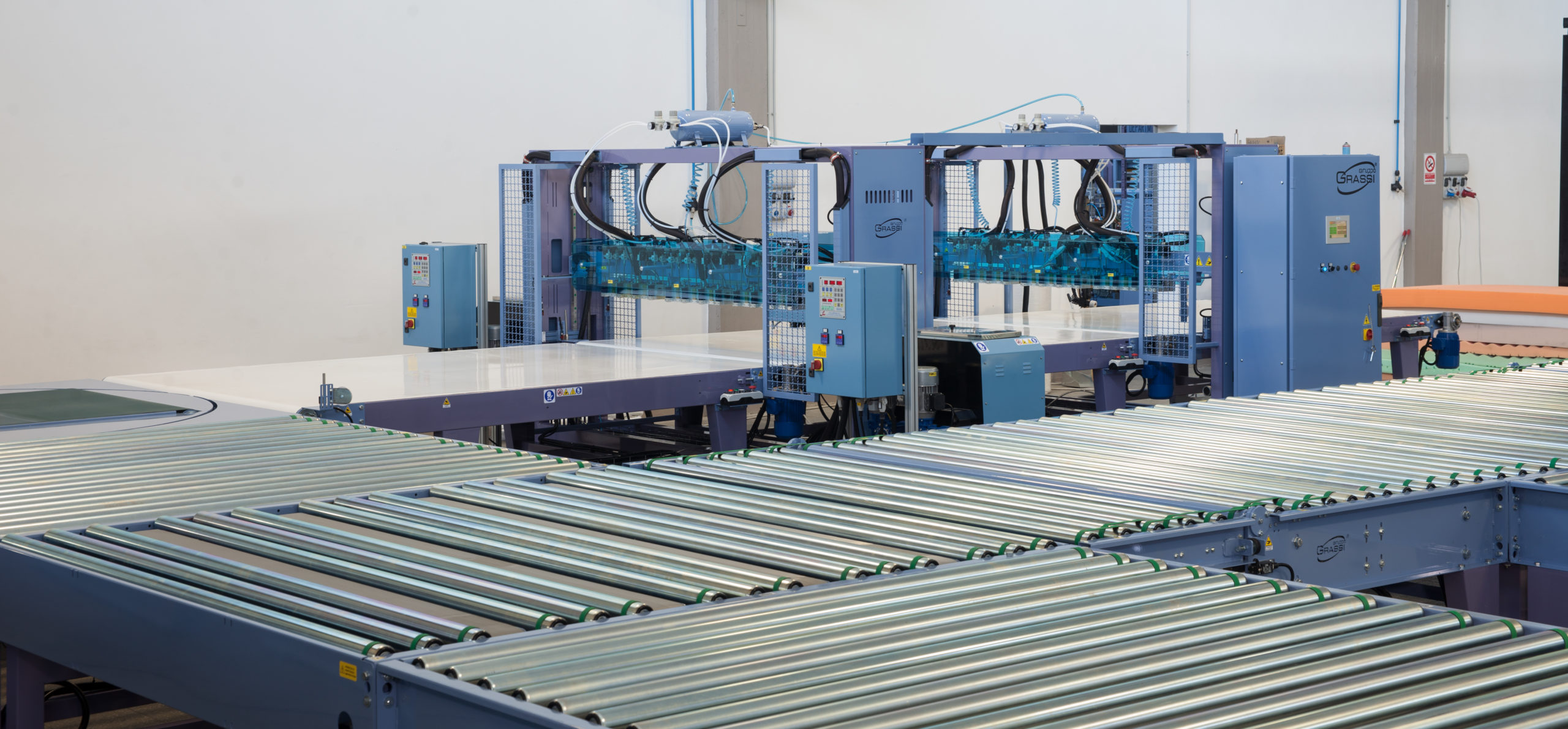

Automatic line for hot-melt glueing.

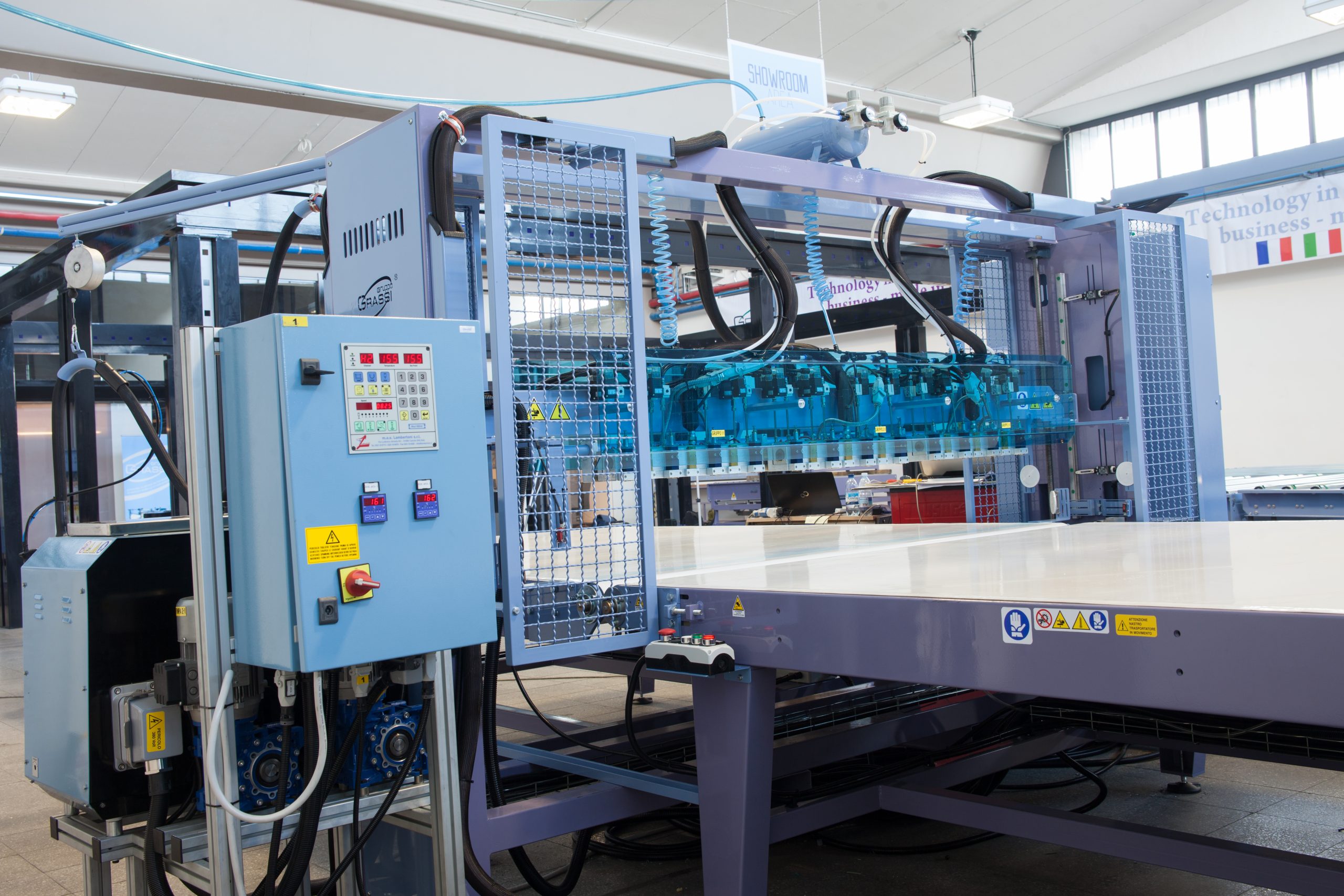

Spray control unit.

Unique, highly productive and functional, it automates the operation of glueing and assembly of the outer covering of the mattress, preparing it for final edging and sewing.

LINE G 6002 constantly manages the amount of glue according to the type of product, regardless of size or shape, it sets the glueing points in relation to customized programs and recipes, quantifying a definite cost regardless of the operator.

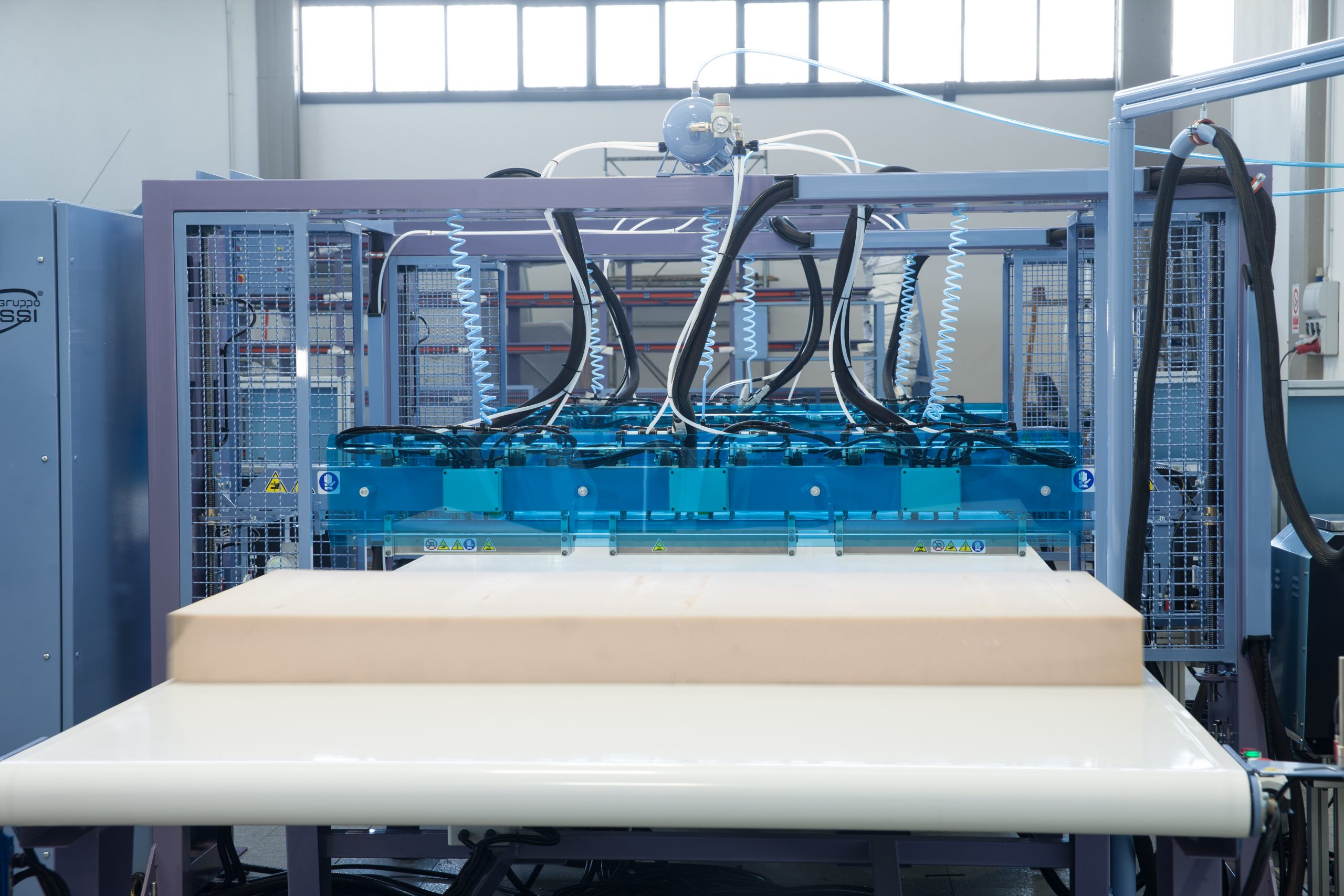

The Spray function with independent modules greatly facilitates glueing over the entire surface of the sheet.

The machine LINE G 6002 consists of:

- 3 feeding belts with 5 plies in non-stick silicone

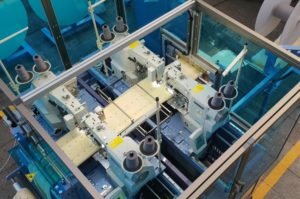

- 2 Automatic programmable glueing modules complete with:

- 6 central glueing heads with 4 independent nozzles each and Spray / Shank function

- 2 Automatic programmable glue melters, independent heating for bath, hoses and spray guns, ceramics gear pumps controlled by a microprocessor.

AVAILABLE VERSIONS:

LINE G 6002: Automatic Hot-Melt line with 2 glueing bridges / production of 1500 parts over 8 hours

LINE G 6002 S: Automatic Hot-Melt line with 1 glueing bridge / production of 750 parts over 8 hours