Description

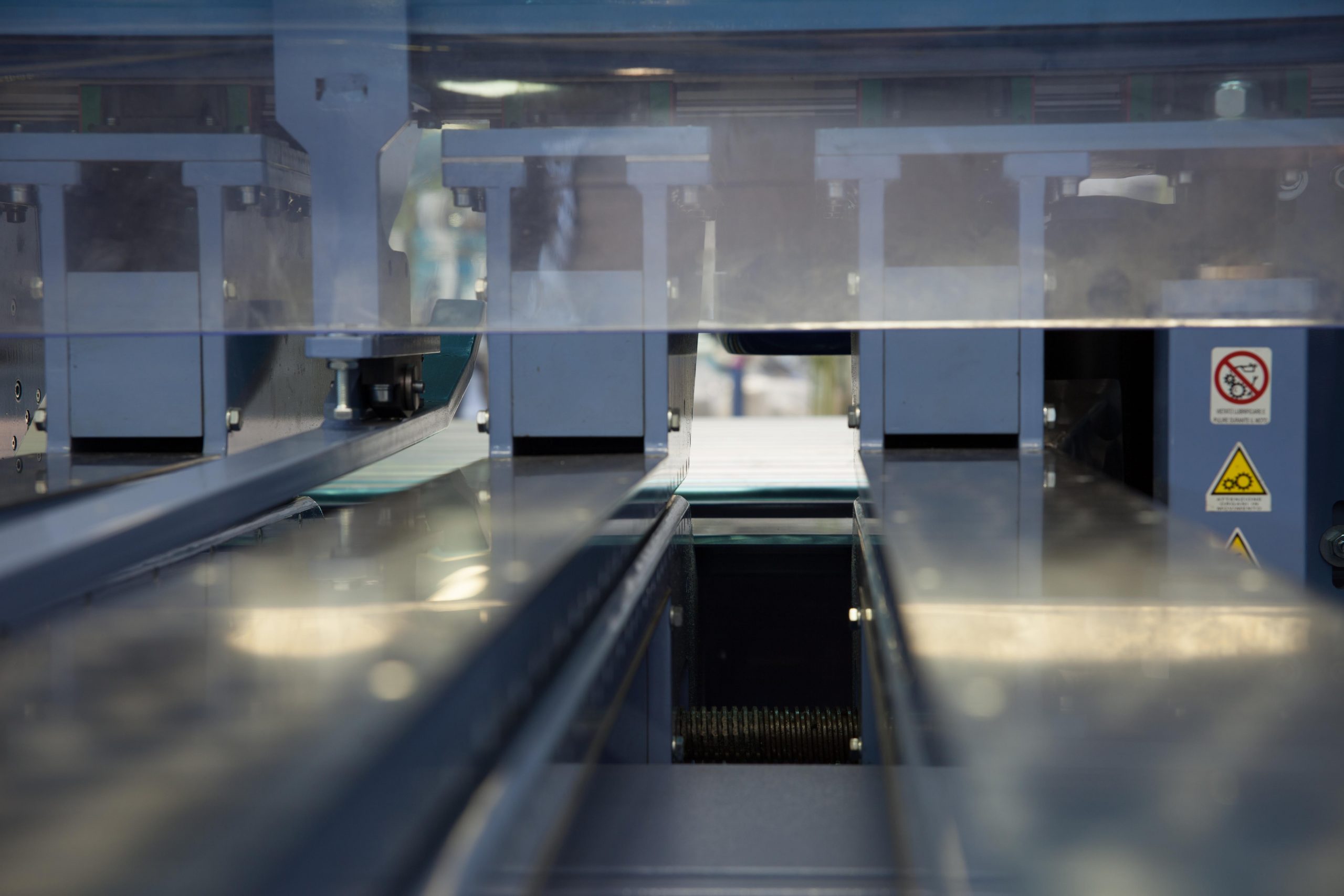

INTRODUCTION CENTERING ROLLER:

Introduction centering roller conveyor to center and align the slab before introduction. Equipped with specific wheels that lift pneumatically and facilitate centering. Ultrasonic sensor for millimetric calculation of the thickness of the slab to be stuffed. Linear potentiometer for calculating the width of the slab to be stuffed.

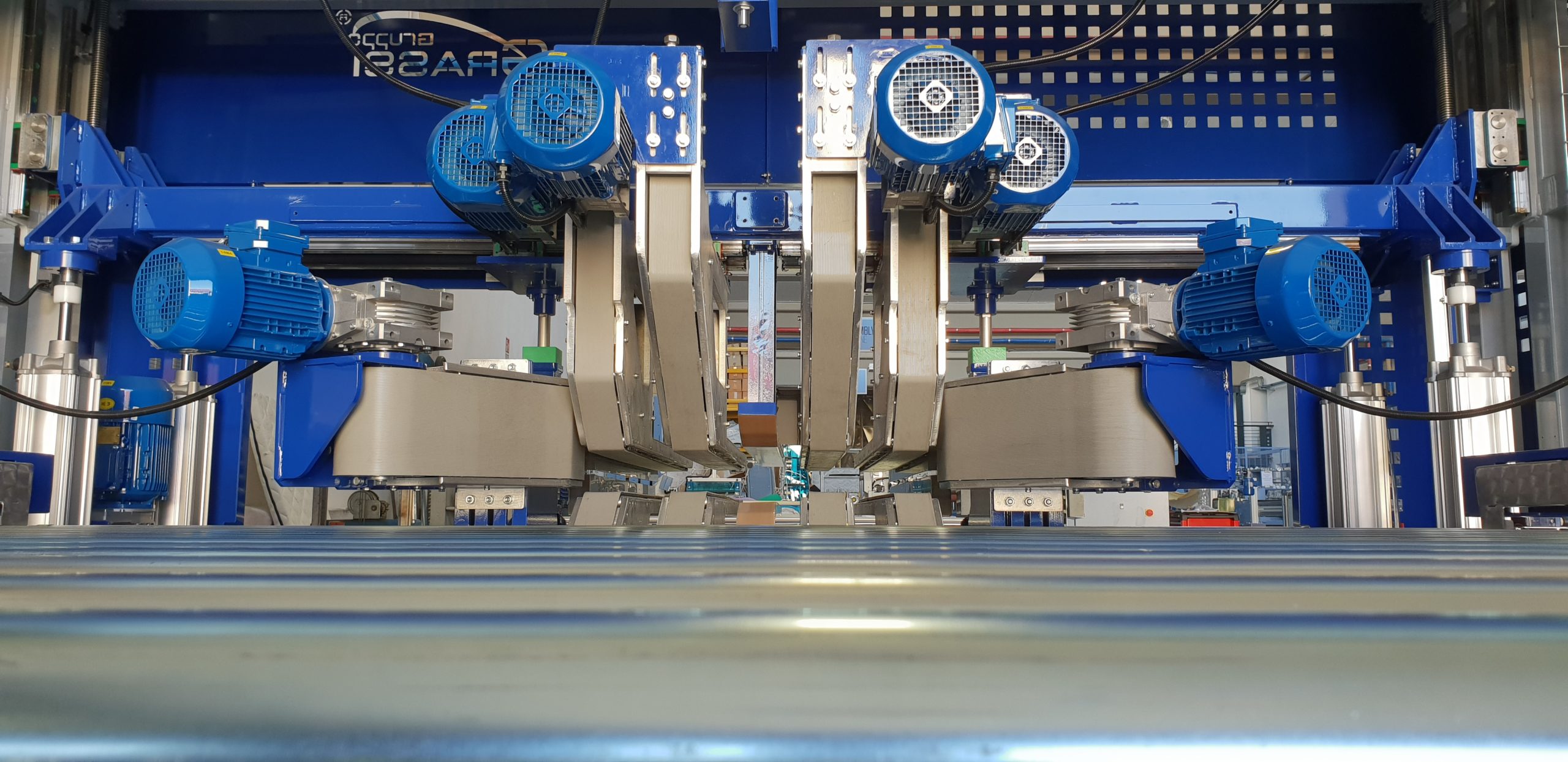

Automatic bagging module to insert rubber sheets (or different ones) in LINING or COVER of Stretch / Jacquard / Flame retardant / etc.

with at least 1 open side. Guarantee of uniformity of pressure over the entire surface.

The lateral and height compression parameters are set from the Touch-screen panel.

Independent motorized belts with n. 10 motors and gearmotors.

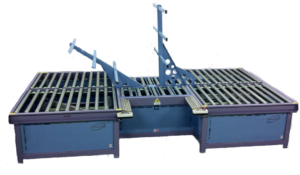

Spout for loading cover / lining covered in very slippery stainless steel.

Surface sides coated with Teflon to facilitate the sliding of even more rigid slabs.

Ribbon composition:

– N. 4 upper mobile TAPES

– N. 4 lower mobile TAPES

– N. 2 mobile side compression

TAPES The machine calculates and changes its size automatically according to the slab measured on the centering roller.

All belts are mounted on two mechanical nuts and translate perfectly symmetrical from 60cm minimum to 220cm maximum.